Why 5052 Aluminum Sheet?

5052 aluminum sheet is known for its excellent balance of strength, formability, and corrosion resistance. These properties make it particularly suited for automotive applications where the material needs to withstand high temperatures and harsh environments.

Key Benefits of Using 5052 Aluminum Sheet:

Good Corrosion Resistance: Essential for ensuring long-term durability, especially in areas with varying weather conditions.

High Strength-to-Weight Ratio: Reduces overall vehicle weight without compromising structural integrity, enhancing fuel efficiency.

Excellent Formability: Allows for easy fabrication into complex shapes required for heat shields.

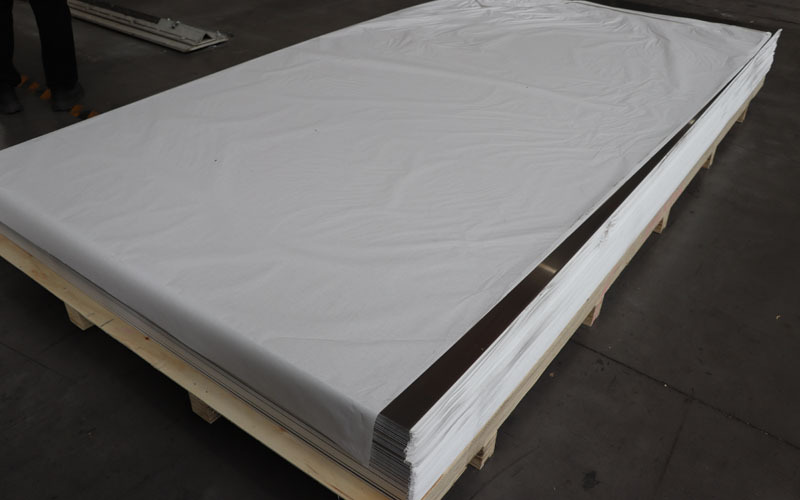

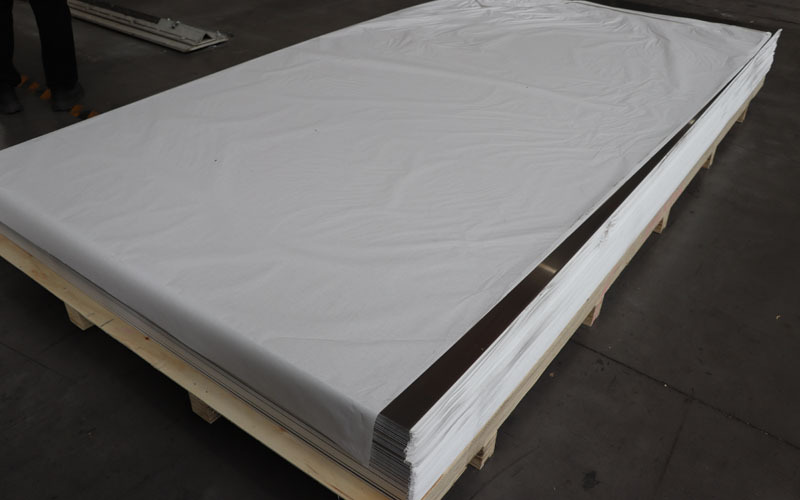

Likely Product Forms: Aluminum Plates vs Aluminum Coils

Canadian customers sourcing 5052 aluminum sheet for automotive heat shields may opt for either aluminum plates or aluminum coils.

Aluminum Plates: Typically used when thicker pieces are required, which may be necessary for certain structural applications of heat shields.

Aluminum Coils: More flexible for applications requiring continuous lengths or rolled configurations, likely preferred for intricate designs or when processing involves multiple bending operations.

Size Specifications

The dimensions of the 5052 aluminum sheet being purchased likely fall within the following ranges:

Thickness: Generally between 1.5mm and 3mm. Thicker plates may be used in areas exposed to extreme heat or abrasion.

Width: Common widths for both plates and coils range from 1000mm to 1500mm, depending on the specific requirements of the heat shield design.

Length: For aluminum coils, lengths can vary, while aluminum plates may range from 2000mm to larger custom sizes based on specific vehicle designs.

Applications in Automotive Heat Shields

The heat shields manufactured from 5052 aluminum sheet can be found in various types of vehicles, including:

Passenger Cars: Heat shields protect sensitive components like fuel tanks and exhaust systems from heat produced by the engine and the exhaust system.

Light-Duty Trucks: Used in areas where the engine transmits significant heat, especially in trucks that carry heavy loads or operate in demanding conditions.

SUVs and Recreational Vehicles (RVs): Larger vehicles that require substantial heat protection to ensure the safety and longevity of critical engine and electrical components.

Key Components of Automotive Heat Shields

Engine Heat Shields: Protect the engine compartment and surrounding components from extreme heat, ensuring optimal performance.

Exhaust Heat Shields: Shield the undercarriage and other delicate components from the heat generated by the exhaust system.

Fuel Tank Shields: Layer of protection for fuel tanks from heat sources, preventing potential vaporization and maintaining safe fuel levels.

Conclusion

The growing use of 5052 aluminum sheet for automotive heat shields among Canadian customers reflects a demand for reliable durable materials that can withstand harsh environments while providing effective heat management. By sourcing the correct form, whether plates or coils, and the appropriate dimensions, manufacturers can produce effective heat shields for various vehicle types.

For inquiries about our high-quality 5052 aluminum sheet products for automotive applications, please contact us today. Our team is ready to assist you with your specific needs and help you choose the right materials to enhance your vehicle designs.