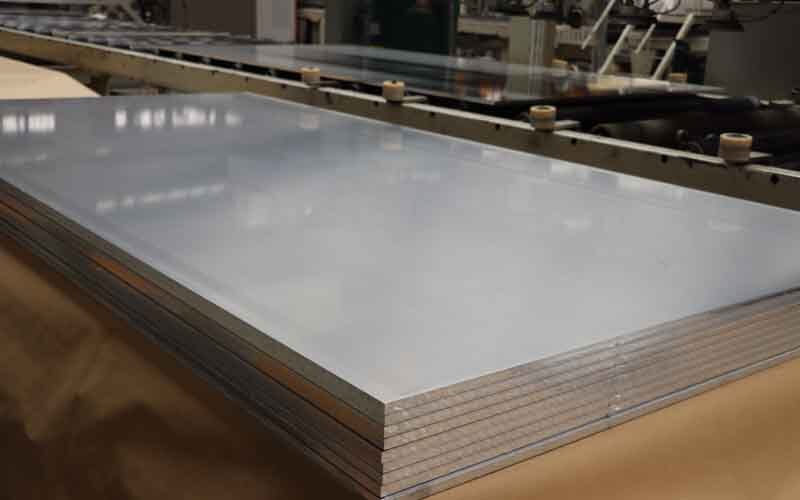

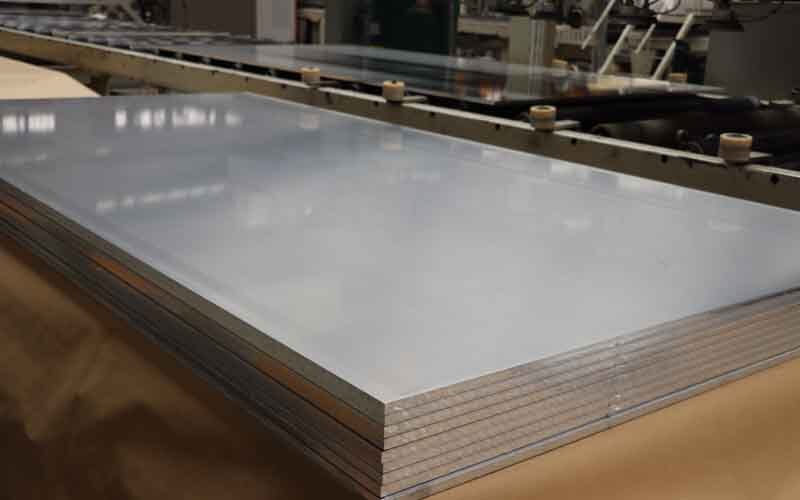

Why Choose Our Aluminum Sheets for Automotive Parts?

1. Engineered for Indonesia’s Climate & Demands

Alloys: 5052-H32 & 6061-T6

Key Features:

High Corrosion Resistance: Withstand tropical humidity, salt air (coastal areas), and road chemicals.

Lightweight Strength: 30% lighter than steel, ideal for fuel-efficient motorcycles & cars.

Formability: Perfect for stamping motorcycle fenders, car door panels, and engine brackets.

2. Precision Customization

Cut-to-Size: cutting for parts like:

Motorcycle frames

Truck chassis components

EV battery casings

Certifications & Compliance

Global Standards: ISO 9001.

Documentation: Mill Test Certificates (MTC) & Material Safety Data Sheets (MSDS).

Applications in Automotive Manufacturing

Part Type | Recommended Alloy | Thickness |

Motorcycle Fuel Tanks | 5052-H32 | 1.2–2.0mm |

Car Door Panels | 6061-T6 | 1.5–3.0mm |

EV Battery Trays | 5754-H111 | 2.0–4.0mm |

Cost-Saving Solutions for Indonesian Factories

Bulk Discounts: Save 12% on orders over 5 tons.

Scrap Buyback Program: Return unused cuttings for credit.

JIT Delivery: Synchronize with your production schedule.

Case Study: Partnering with a Surabaya Motorcycle Parts Maker

Challenge: A client needed corrosion-resistant aluminum for 10,000+ motorcycle fuel tanks monthly.

Our Solution:

Supplied 5052-H32 sheets with pre-applied protective film.

Result: Reduced material waste by 18% and won a Yamaha supplier contract.

Get a Free Sample Kit!

200x200mm samples (5052 & 6061 alloys)

Email sales01@mingtai-al.com

Why 300+ Indonesian Factories Trust Us

Customs Assistance: Handle HS Code 7606.12.90 clearance.

Certifications & Partners

ISO 9001:2015