Why 5052 Aluminum Sheets Are Ideal for German Luggage Production

Germany’s renowned luggage industry relies on 5052 aluminum sheets for their exceptional strength lightweight properties, and corrosion resistance. Here’s what manufacturers need to know:

Key Specifications for 5052 Aluminum Sheets

Thickness Range: 0.5mm to 2.0mm, balancing durability and weight for luggage frames, shells, and handles.

Temper States:

H32: Offers a perfect blend of strength and formability, ideal for luggage components.

H34: Provides higher strength for heavy-duty applications like reinforced frames.

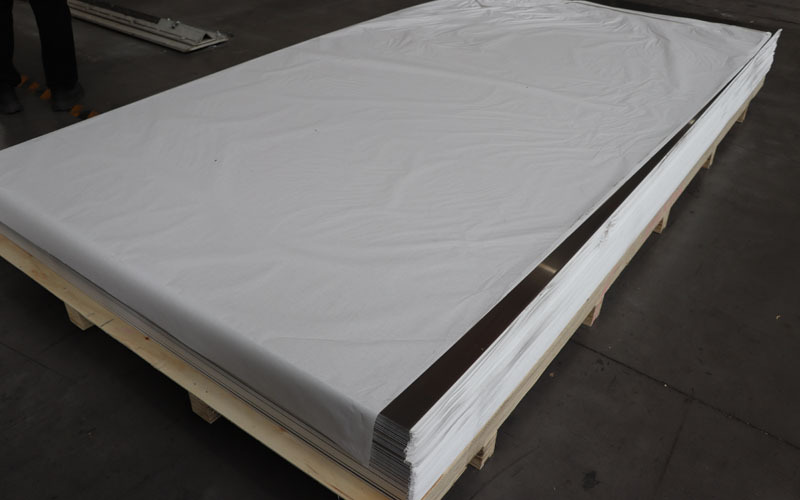

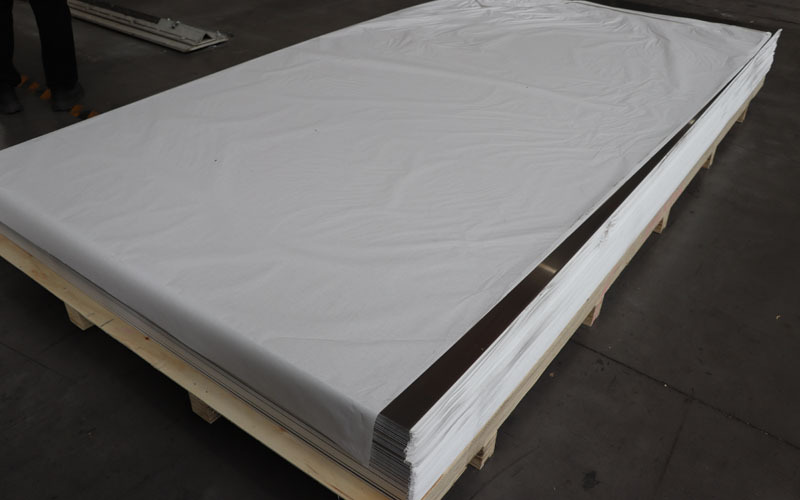

Sheet Sizes: 1000x2000mm, 1200x2400mm, or custom cuts to fit specific designs.

Quality Requirements for Luggage Manufacturing

Surface Finish: Smooth, defect-free surfaces for aesthetic appeal and easy coating.

Corrosion Resistance: Essential for travel cases exposed to varying climates.

Formability: Easy to bend and shape without cracking, ensuring precise designs.

Certifications: EN and ISO standards compliance for quality assurance.

Why German Manufacturers Choose 5052 Aluminum

Lightweight: Reduces luggage weight without compromising strength.

Durable: Withstands frequent use and harsh travel conditions.

Versatile: Suitable for luxury, mid-range, and affordable luggage lines.

Key Applications in Luggage Production

Frames & Shells: Provides structural integrity and sleek finishes.

Handles & Reinforcements: Ensures durability and ergonomic comfort.

Decorative Panels: Adds a premium look to high-end travel cases.

Supporting Germany’s Luggage Industry

From luxury brands in Munich to industrial manufacturers in Berlin and Frankfurt, our 5052 aluminum sheets meet the highest standards for quality and performance.

Contact Us Today!

Email sales01@mingtai-al.com or visit aluminumsheetstrailers.com for quotes, certifications, and bulk orders. Elevate your luggage production with premium 5052 aluminum!