a) Why choose 5754 aluminium for fuel tanks?

Resistance to rust, humidity and snowmelt

In Canada, where snowmelt is heavily used in winter, ordinary metal fuel tanks are prone to rust and corrosion. 5754 aluminium plate contains magnesium, which is naturally resistant to corrosion. Even when exposed to salt or humid air for a long period of time, the surface will not rust, reducing maintenance costs.

Weight is 15-20% lighter than iron fuel tanks

Aluminium is only one-third the density of steel, and fuel tanks made from 5754 aluminium sheet directly reduce the weight of the bodywork. For every 100kg of weight reduction, trucks can save about 0.5 litres of fuel per 100km, saving thousands of Canadian dollars in annual fuel costs for long-distance transport.

Aluminium is not easy to break in a collision, which makes it safer.

Aluminium has good ductility and can absorb the impact when encountering bumps or minor collisions, avoiding fuel leakage. The all-welded process further strengthens the structure, and the strength of the welded seam is the same as that of the plate.

b) Four core advantages of 5754 aluminium fuel tanks

Stable low-temperature performance: -40°C environment still maintains toughness, no risk of brittle cracking.

Simple forming and processing: it can be produced quickly by roller pressing, stamping and other processes, and supports customised shapes.

100% recyclable: more than 85% of the material can be re-melted at the end of its life, complying with Canadian environmental regulations.

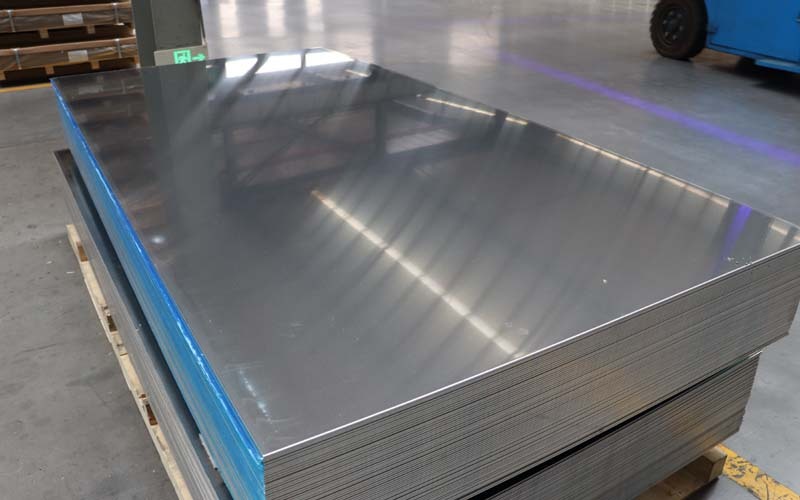

No-paint appearance: beautiful silver metallic texture, eliminating the need for painting and reducing production costs.

c) Why do Canadian transport companies need it?

Coping with extreme weather: In the northern region, where winters are harsh and traditional fuel tanks are prone to cracks due to low-temperature contraction, 5754 aluminium panels have a lower coefficient of thermal expansion and are more stable.

Meet environmental requirements: The Canadian government encourages the use of recyclable materials, and aluminium fuel tanks are more biodegradable and non-polluting than plastic tanks.

Reduce operating costs: Lightweight design reduces tyre wear and prolongs vehicle maintenance intervals.

d) Production process and quality assurance

Laser cutting and argon arc welding technology are adopted to ensure the sealing of the fuel tank. Each batch of aluminium plates passes tensile strength test (165-265MPa), which is in line with international transport container standards. Finished products are verified by air pressure test and anti-leakage, with a life span of more than 10 years.

Contact Mingsheng