Introduction

In the automotive manufacturing industry, lightweight yet durable materials are critical for optimizing performance and fuel efficiency. 3003 aluminum alloy has emerged as a top choice for fuel tank components due to its exceptional corrosion resistance, formability, and cost-effectiveness. At Henan Mingsheng Aluminum Co., Ltd. , an ISO-certified manufacturer,we specialize in supplying high-quality 3003 aluminum sheets and coils tailored for fuel tank production. With ready-to-ship inventory and over 20 years of expertise, we empower global manufacturers to streamline their supply chains and meet demanding project timelines.

Applications of 3003 Aluminum Alloy in Vehicle Fuel Tanks

3003 aluminum alloy’s unique properties make it ideal for the following fuel tank components across multiple vehicle types:

1. Commercial Trucks & Trailers

o Fuel Tank Shells: The alloy’s resistance to road salt, chemicals, and moisture ensures long-term durability for heavy-duty applications.

o Baffle Plates: Its excellent formability allows for seamless shaping of internal baffles to prevent fuel sloshing.

2. Passenger Vehicles

o Tank Covers & Flanges: Precision-stamped covers and flanges benefit from 3003’s weldability and leak-proof performance.

3. Agricultural & Construction Machinery

o Reinforcement Brackets: The alloy’s strength-to-weight ratio supports heavy machinery tanks exposed to harsh environments.

4. Marine & Off-Road Vehicles

o Corrosion-Resistant Connectors: Critical for components exposed to saltwater or rugged terrains.

Why Choose Mingsheng’s 3003 Aluminum for Fuel Tanks?

Superior Material Properties:

High manganese content enhances corrosion resistance.

H22 temper ensures optimal hardness and formability.

Recyclable & eco-friendly (partially made from recycled aluminum).

Quality Assurance & Certifications:

o ISO-certified production processes ensure consistent quality and compliance with international standards.

o Rigorous testing protocols for thickness tolerance, surface finish, and mechanical properties.

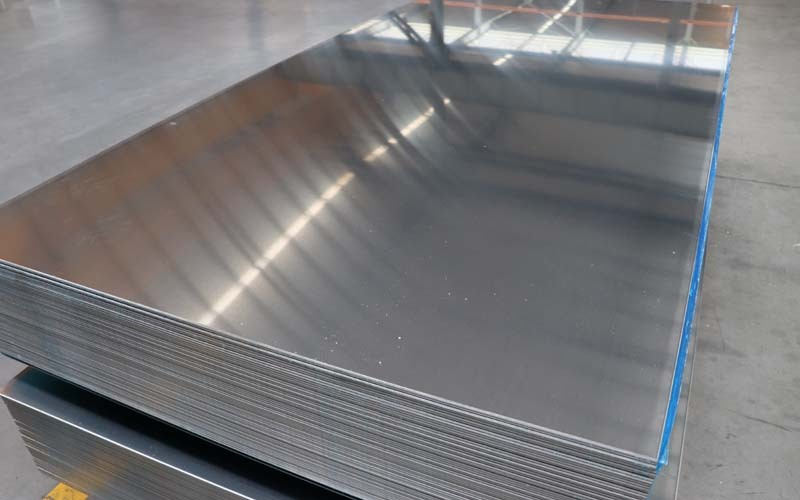

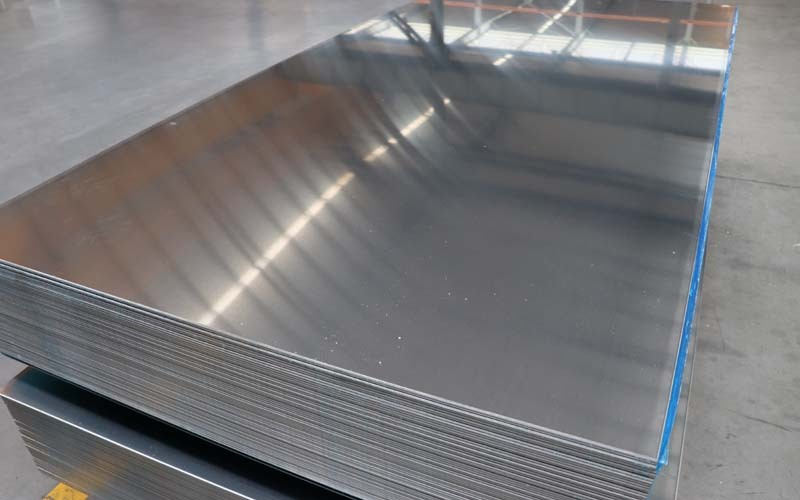

Ready-to-Ship Inventory:

Specification: 3003 H22 | Thickness: 2mm | Size: 740mm x 1320mm

Quantity: 645 sheets (3.46 tons) available immediately.

Packaging: Single transparent 80/1-CLEAR interleaving film + Grade-A box packaging for safe global delivery.

Fast Turnaround: Skip production delays—shipments can be dispatched within 48 hours.

Case Study: Success in Malaysia

A leading automotive parts manufacturer in Malaysia recently sourced Mingsheng’s 3003 H22 sheets to produce gasoline vehicle fuel tanks. By partnering with an ISO-certified supplier, they reduced lead times by 60% and secured a lucrative OEM contract.

Partner with Mingsheng for Reliable Fuel Tank Solutions

As a trusted ISO-certified supplier to global automotive brands, Mingsheng Aluminum combines cutting-edge production facilities in Gongyi and Zhengzhou with a customer-centric sales team. Whether you need standard specifications or custom-sized coils, we deliver quality and speed.

Act Now!

Contact us today to request samples, pricing, or technical specifications. Let’s turn your fuel tank project into a success story!

Email: sales01@mingtai-al.com

Website: aluminumsheetstrailers.com