Introduction

As the automotive industry prioritizes efficient thermal management, 1060 aluminum alloy has become a cost-effective and reliable material for radiator manufacturing. Known for its exceptional thermal conductivity, formability, and corrosion resistance, 1060 aluminum is widely used in both conventional and electric vehicle cooling systems. At Henan Mingsheng Aluminum we supply high-purity 1060 aluminum sheets and coils tailored for radiator production. Let’s explore its global demand and optimal specifications.

Why 1060 Aluminum is Ideal for Radiators

1. Thermal Conductivity:

o 237 W/m·K (superior to many alloys), ensuring rapid heat dissipation.

2. Formability:

o Easily stamped into complex fin and tube designs without cracking.

3. Cost Efficiency:

o Lower cost than alloys like 3003 or 5052, ideal for budget-sensitive markets.

4. Corrosion Resistance:

o Withstands coolant chemicals and humid environments.

Target Markets: Which Countries Use 1060 Aluminum Radiators?

1. Emerging Economies:

o India: High demand for affordable commercial vehicle radiators (trucks, buses).

o Mexico: Growing auto parts manufacturing hub serving North America.

o Thailand: Automotive OEMs targeting cost-effective cooling solutions.

2. Aftermarket-Driven Regions:

o Middle East & Africa: Harsh climates increase radiator replacement demand.

o Southeast Asia: Motorcycle and small-engine vehicle radiators.

3. Electric Vehicle (EV) Markets:

o Brazil, Indonesia: Early-stage EV adoption with focus on affordable thermal systems.

Recommended Specifications for Radiator Manufacturing

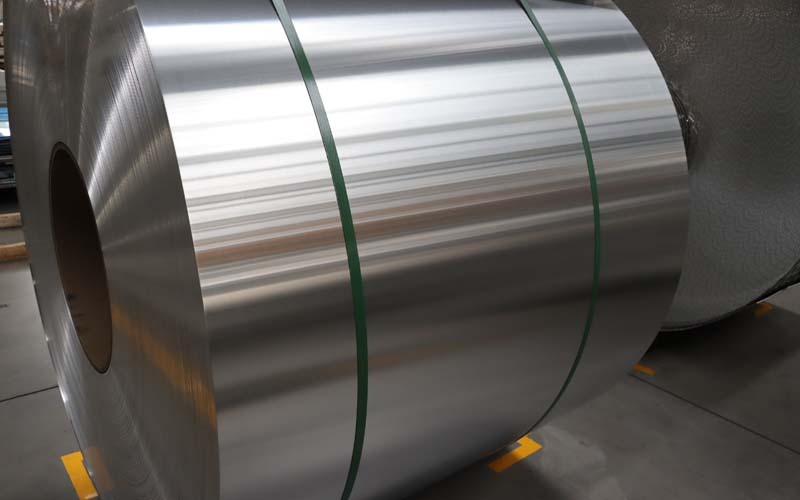

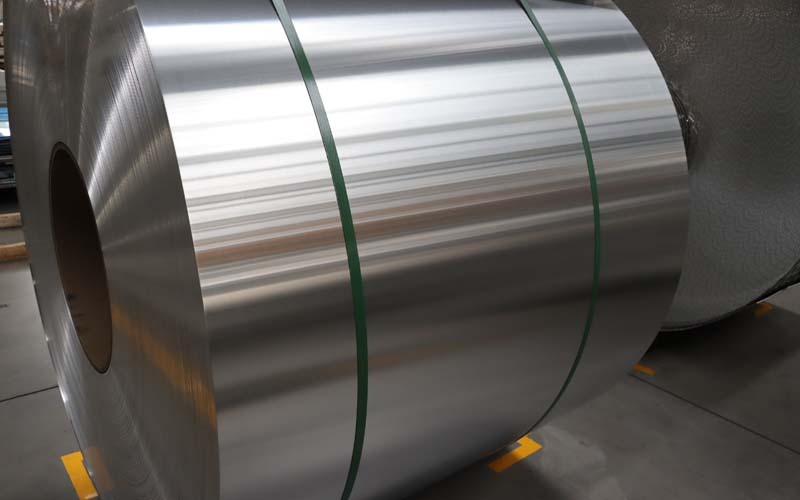

1. Material Form:

o Aluminum Coils (Most Common):

§ Suits high-volume, continuous stamping processes for radiator fins and tubes.

o Sheets: Used for custom or small-batch production.

2. Thickness:

o Fins: 0.1mm–0.2mm (ultra-thin for maximizing surface area).

o Tubes/Headers: 0.5mm–1.0mm (structural components).

3. Width:

o Coils: 1000mm–1500mm (standard widths for automated stamping lines).

o Sheets: Custom cuts up to 2650mm.

4. Temper:

o H18 (Full Hard): For radiator fins requiring stiffness.

o O (Annealed): For deep-drawn tube components.

Why Choose Mingsheng’s 1060 Aluminum?

High Purity: 99.6%+ aluminum content for optimal thermal performance.

Certifications: ISO 9001, ASTM B209, and RoHS compliance.

Global Logistics:

Coil Weights: 3–10 tons/coil, optimized for 20ft/40ft containers.

Fast shipping to key ports like Mumbai, Dubai, and Santos.

Custom Slitting:

Pre-slit coils to reduce on-site processing costs.

Case Study: Radiator Manufacturer in India

A Pune-based auto parts supplier switched to Mingsheng’s 1060-H18 coils (0.15mm x 1200mm) for Tata Motors’ truck radiators. Results:

15% lower material costs vs. 3003 aluminum.

20% faster production with consistent coil quality.

Zero corrosion failures in monsoon conditions.

Upgrade Your Radiator Production Today!

Whether you’re serving budget-conscious markets or scaling EV thermal systems, Mingsheng’s 1060 aluminum delivers unmatched value and reliability.

Contact Us For:

1060 Coil/Sample Pricing

Technical Data Sheets

Custom Slitting Services

Email: sales01@mingtai-al.com

Website: aluminumsheetstrailers.com